Company

History

ElleK Automazioni was established in 1999 and, after 10 years of activity, is now operating in Arceto di Scandiano, the new office where all administration, commercial and production operations have been transferred to. During this time, ElleK has expanded its business considerably, adding a rich variety of advanced technologies and products to the original core activities which were based on the production of electrical systems and control panels. ElleK has therefore undergone a "Second foundation", characterised by a series of structural reforms aimed at making the company more competitive and guaranteeing better service. ElleK has adopted an aggressive Research and Development and capital investment policy, which materialised in the development of key sectors such as Ceramics, Food, Food Processing, Plastic, iron and steel industry, waters treatment and energy savings. The entire technical staff is already working on developing future business opportunities and expanding existing services. In addition to visibly reinforcing brand identity, the introduction of the new company logo is a concrete expression of the transformation that is taking place and its commitment to future development.

Fields of Operation

- Development and production of electric automation and industrial electronics technologies

- Hardware and software systems

- Process control and monitoring

- On-board machine systems

- Control panels

- Hardware and software systems

- Process control and monitoring

- On-board machine systems

- Control panels

Mission

The company mission of Ellek Automazioni is: providing a highly professional consulting service, aimed at meeting the customer's needs in the most functional and specific manner; planning and carrying out this solution in a concrete manner by installing the necessary machinery and carrying out all start-up tests in order to deliver well-tested systems in perfect working order and providing the necessary post-sale services, such as training the assigned personnel as well as immediate technical assistance.

Vision

The company vision is expressed in terms of the ongoing will to keep extraordinarily up to date with specific innovations in the field, which occur at an extremely rapid pace, in order to set itself apart from its competitors in the market by providing state-of-the-art solutions, thus becoming a true partner for its customers.

Automation and robotics

since 1999

Discover an effective, punctual and professional partner.

How we work

Productive process

1

TECHNICAL REQUEST

One of our experts visits the customer’s site to collect all the technical specifications needed to define the exact requirements to fulfil and on the basis of which to design the supply.

2

FEASIBILITY STUDY

The technical specifications gathered in the previous phase are analysed by our design team and the most suitable solution is identified.

3

OFFER

The solution identified in the previous phase is transformed into a concrete and specific offer by our technical sales office

4

SOFTWARE DESIGN

As soon as the offer is accepted, our programmers start to design the best possible PC and PLC software solutions to control the customer’s production process.

1

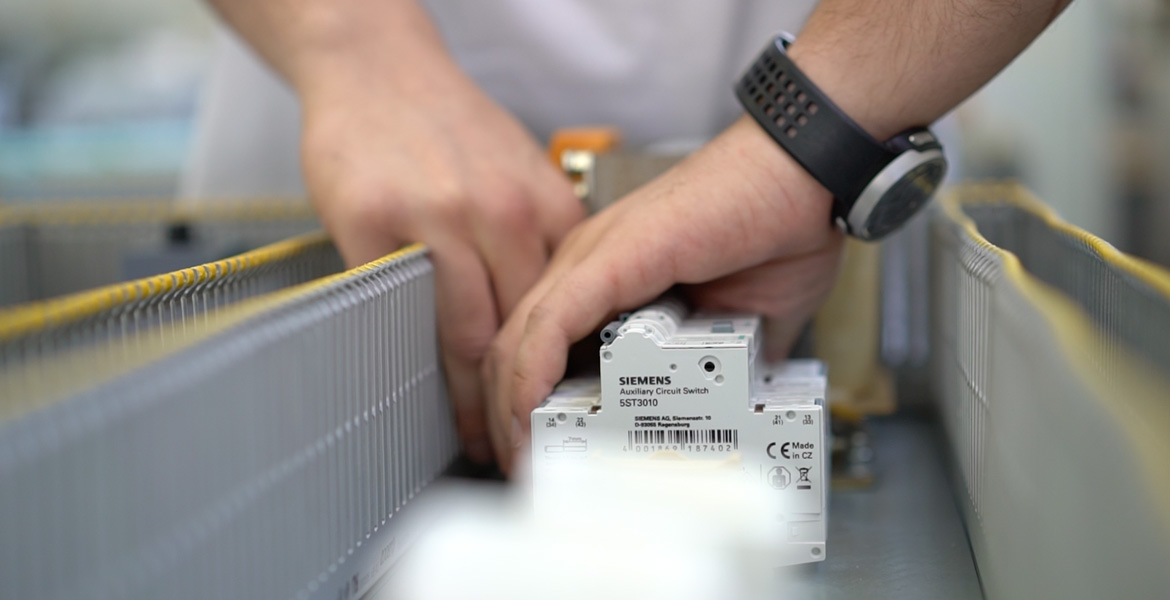

HARDWARE DESIGN, MANUFACTURING AND INSTALLATION

In parallel with software development, our hardware design team generates a detailed design for forwarding to our assembly workshop. Our assembly workshop manufactures all the necessary parts and sends its own team of specialists to install them at the customer’s site.

2

SOFTWARE INSTALLATION AND PLANT COMMISSIONING

When all mechanical installations have been completed, the PC and/or PLC software is installed and tested, culminating in whatever commissioning the customer requires.

3

AFTER SALES SERVICE

When all installation work has been finished, Elle K Automazioni trains the customer’s personnel in the running of the new plant. Training can take place anywhere in the world, and is always performed by our own team of experts.